Australia excels in remote operations and robotics in harsh environments on a large scale – and this can be used on Earth or in space.

Australia’s ingenuity in mining and resources has captured the attention of international space partners. These partners are planning to incorporate our homegrown technology and expertise in future space exploration missions, such as Artemis.

There is a clear crossover with the technology being used for mining and resources activities on Earth and its possible uses in space to support science and exploration goals.

Australia operates automated trucks, trains and equipment on mining sites 1,500 kilometres away from Perth in the Pilbara region of Western Australia. It can leverage this remote operations experience to support a wide range of off-Earth activities. This includes lunar exploration, or the construction, maintenance, and repair of lunar infrastructure, which we define as Foundational Services to support science.

By connecting space with robotics and remote operation capabilities, we can also make these capabilities stronger, rugged and more sophisticated. We can advance the mining and resources industry here on Earth by improving productivity and fast-tracking critical technologies.

The resources technologies with applications for space:

Mining crews can make calculated decisions and determine precise drilling targets, using information from Earth observation satellites that are examining the landscape. Communications satellites stream enormous amounts of data in real time. This tells workers everything from the position of a vehicle to where the next discovery might be.

Digital twin technology and robotics, such as robotic arms, can perform maintenance and refuel machinery and equipment remotely. This saves on costs and resources of sending a human across long distances, whether it’s in Earth or in space. Digital twins can also be used to virtually simulate all kinds of scenarios before taking the physical risks.

Just like in space, robotic machines and drones can go places on Earth where humans can’t. This minimises environmental risk to workers and avoids possible human error. Robotics is particularly important in harsh environments with extreme temperatures, or within spaces that are elevated, confined or otherwise difficult to reach.

AI designed for lunar rovers, which helps them to explore rugged off-Earth landscapes, can help autonomous vehicles navigate challenging terrain and obstacles on Earth. This technology can also help space launch vehicles and satellites find their way through complex trajectories.

Fully uncrewed autonomous assets can be controlled by sophisticated remote operations infrastructure, whether it’s for terrestrial resources operations or space missions. These centres use cross-cutting technologies including robotics, AI, software simulation and advanced manufacturing.

Computers use complex mathematical algorithms to monitor equipment efficiency and process massive amounts of data. Advanced 3D modelling software can be used to keep equipment on track and ensure vehicles are operating at their best. Space also supports the development of fast and power efficient edge computers.

Case study: Fleet Space Technologies

Exosphere

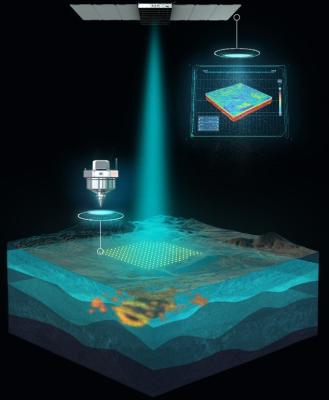

South Australian based company, Fleet Space Technologies, developed a passive, non-invasive mining solution known as ExoSphere by Fleet®.

The Australian Space Agency helped incubate this technology with funding via its Moon to Mars initiative.

ExoSphere, which takes the form of a geode sensor, enables exploration down to two kilometres beneath the Earth’s surface.

By leveraging Fleet’s satellite constellation, ExoSphere identifies prime drilling targets where critical minerals, such as lithium, are located – making the whole process faster, more accurate and less environmentally invasive than ever before.

It’s a huge win for mining and has inspired new ways of searching for minerals in space.

Caption: Exosphere by Fleet.

Image credit: Fleet Space Technologies

SPIDER

Fleet Space Technologies scaled its ExoSphere technology for applications on the Moon. They developed the SPIDER (Seismic Payload for Interplanetary Discovery, Exploration and Research).

SPIDER will record natural seismic waves on the Moon’s subsurface continuously for 14 days. The aim of the technology is to provide valuable insights into the mineral profile of the lunar surface, while also helping to identify water ice deposits. Fleet says it will “uncover unprecedented knowledge about the Moon’s geological properties”. SPIDER can provide data about the composition of the lunar crust from the surface all the way to a depth of one kilometre, thereby accelerating the scientific knowledge of the Moon, its composition and origins.

SPIDER’s identification of ice deposits on the lunar surface can produce water. This will enable the long-term human exploration of the Moon, plus can be used for rocket fuel propellant for future missions from the Moon to Mars.

SPIDER will go to the Moon by as early as 2026 aboard the Blue Ghost lunar lander, developed by US based company, Firefly Aerospace.

Image credit: Fleet Space Technologies

Related content:

Why Space Matters