The transition to clean energy presents all kinds of challenges. For one, there’s a growing demand for critical minerals. These are essential for electric vehicles, solar panels and battery storage.

According to CEO and Co-Founder of Fleet Space Technologies Flavia Tata Nardini, the global demand for minerals like lithium, nickel and cobalt is expected to triple by 2050.

“Australia is a significant producer of these critical minerals, with an estimated 8% of the world's reserves,” she says. “But finding new sources using traditional prospecting methods is becoming increasingly costly, complex, time-consuming and environmentally damaging.”

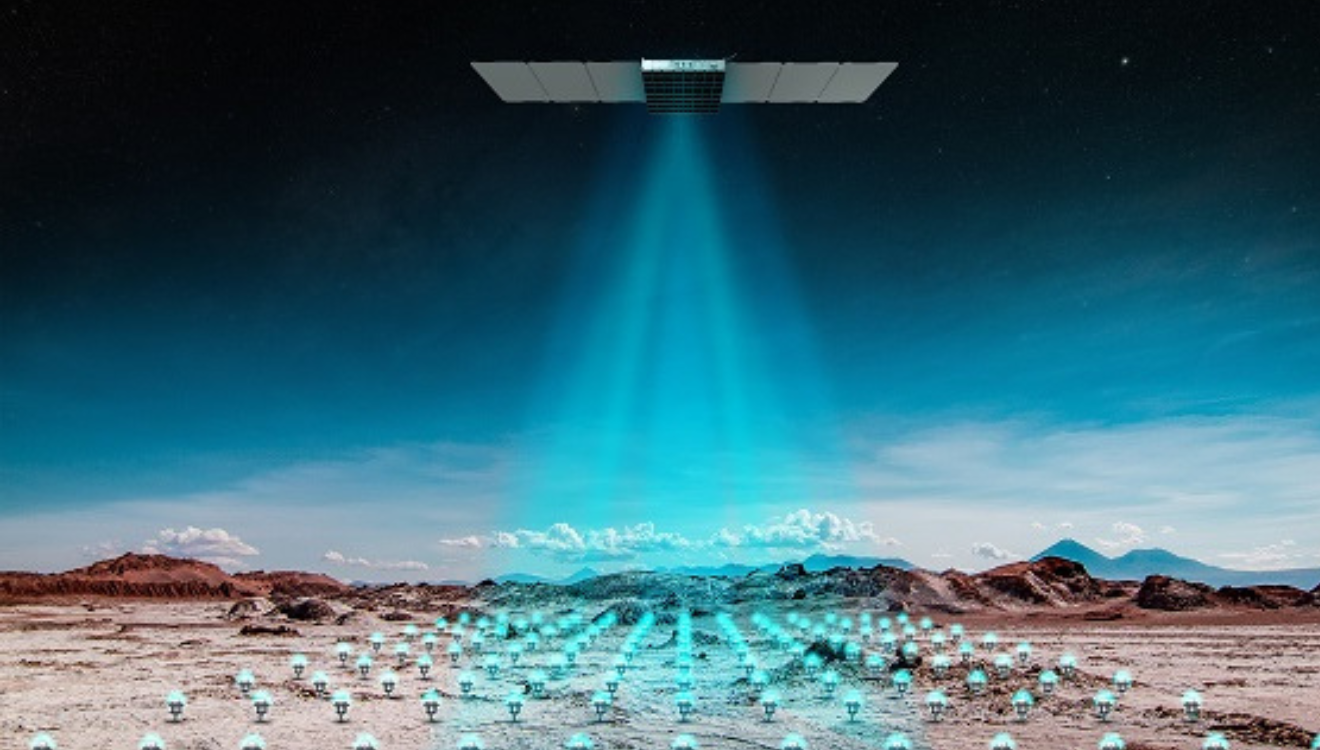

Determined to address this issue, Fleet developed a passive, non-invasive solution at their Adelaide headquarters. The Australian Space Agency helped incubate ExoSphere by Fleet® with funding support through its Moon to Mars Demonstrator Feasibility Grant Program. ExoSphere enables exploration down to two kilometres beneath the Earth’s surface.

“ExoSphere, which leverages Fleet’s satellite constellation, makes the whole process faster, more accurate and less invasive than ever before. It’s a huge win for the mining and energy industries, and the wider world,” Ms Tata Nardini explains.

Three radical technologies working together

ExoSphere maps large regional areas using an innovative, lightning-fast method. Its smaller carbon footprint gives it an edge over traditional exploration techniques and provides myriad benefits to the resources industry.

First, on the ground, explorers deploy a surface array of Fleet’s Geodes. These are small, advanced, low impact ground sensors. They measure ambient seismic noise with 10 times more sensitivity than other sensors. On board edge computing uses advanced signal processing algorithms to pre-process and compress the data.

Next, the Geodes connect to the cloud through Fleet’s low-power satellite network. SpaceX launched Centauri 5, their low Earth orbit small-satellite, in early 2022. Fleet aims to build a constellation of small satellites by mass manufacturing them at the Australian Space Park in Adelaide.

Finally, Fleet’s cloud platform processes the full array of data. It delivers the data, using Ambient Noise Tomography (ANT), to explorers with rich visualisation tools on the ExoSphere web portal. It takes a few days to create a three-dimensional model of the subsurface. This is faster than the weeks or months required for manual, conventional techniques.

Rapid decision making on the ground

Field teams can use ExoSphere data to make quick decisions while on site. It helps them guide their drilling and even retarget surveys to new, promising prospects. This saves significant time as the teams would be ranking different areas and focusing on the ones of interest. These insights translate into less holes in the ground, reduced costs and more discoveries.

ExoSphere is currently being used by companies such as Core Lithium. They’re undertaking exploration activities to expand their lithium resource at depths of over 500 metres. This follows a successful large-scale trial at Core’s Finniss Project near Darwin.

“With ExoSphere we can make real time decisions very quickly, getting onto position that we can define drilling targets quicker,” Core Lithium Exploration Manager Andrew Bennett says.

“When you can accelerate exploration programs, what you are really doing is accelerating your discovery which is a game changer for exploration.”

From mid-2023 ExoSphere will be used at Core Lithium’s other sites across the Northern Territory to support their exploration program.

From the red earth to the black sky

With commercial operations rapidly scaling, Fleet will leverage their satellite manufacturing expertise to develop defence capabilities in the space domain for Australia and its allies.

“For our customers, it’s proving transformational, overcoming significant technical and practical obstacles and creating tremendous new commercial opportunities,” Ms Tata Nardini says.

ExoSphere is being used successfully across projects in North America including Talon and Power Nickel.

“The technology is already being deployed in Australia, America and Canada, but it has applications wherever these minerals exist – its reach is global. We’re excited about realising that potential in the coming years.” she adds.