NSW-based High Earth Orbit Robotics, known as “HEO”, is delivering automated software and developing advanced cameras to provide images and insights on satellites in space. HEO’s mission is to “image anything in the solar system on-demand”.

Satellites can suffer failures from anomalies or potentially collide with space debris. This could disrupt services on Earth we take for granted every day. Cameras on satellites can keep an eye on space objects to monitor their state and detect problems before they occur. HEO is innovating in sustainable practices and “space situational awareness and debris mitigation”.

Adding cameras to satellites

HEO aims to be “responsible custodians of the space domain”, according to HEO’s Co-Founder and CEO Dr Will Crowe.

“We are not developing our own satellites… we repurpose and partner with satellites already in orbit instead of launching our own single-use satellite,” Dr Crowe says.

“We want to work with anyone sending a satellite or orbital transfer vehicle to space.”

As not all satellites contain sensors, HEO offers an “additional capability” in offering proprietary non-Earth imaging sensors that can be easily hosted by any satellite, according to Dr Crowe.

Once these satellites connect to HEO’s software platform, HEO Inspect, they can provide coverage of spacecraft above or below around 100 kilometres of their regular orbit and feed captured images into the HEO Inspect software platform.

Their proprietary software, HEO Inspect, is on the lookout for imaging opportunities between satellites and space objects. It finds a window when HEO’s partner satellite is having downtime from its primary mission and is “flying-by” another space object of interest.

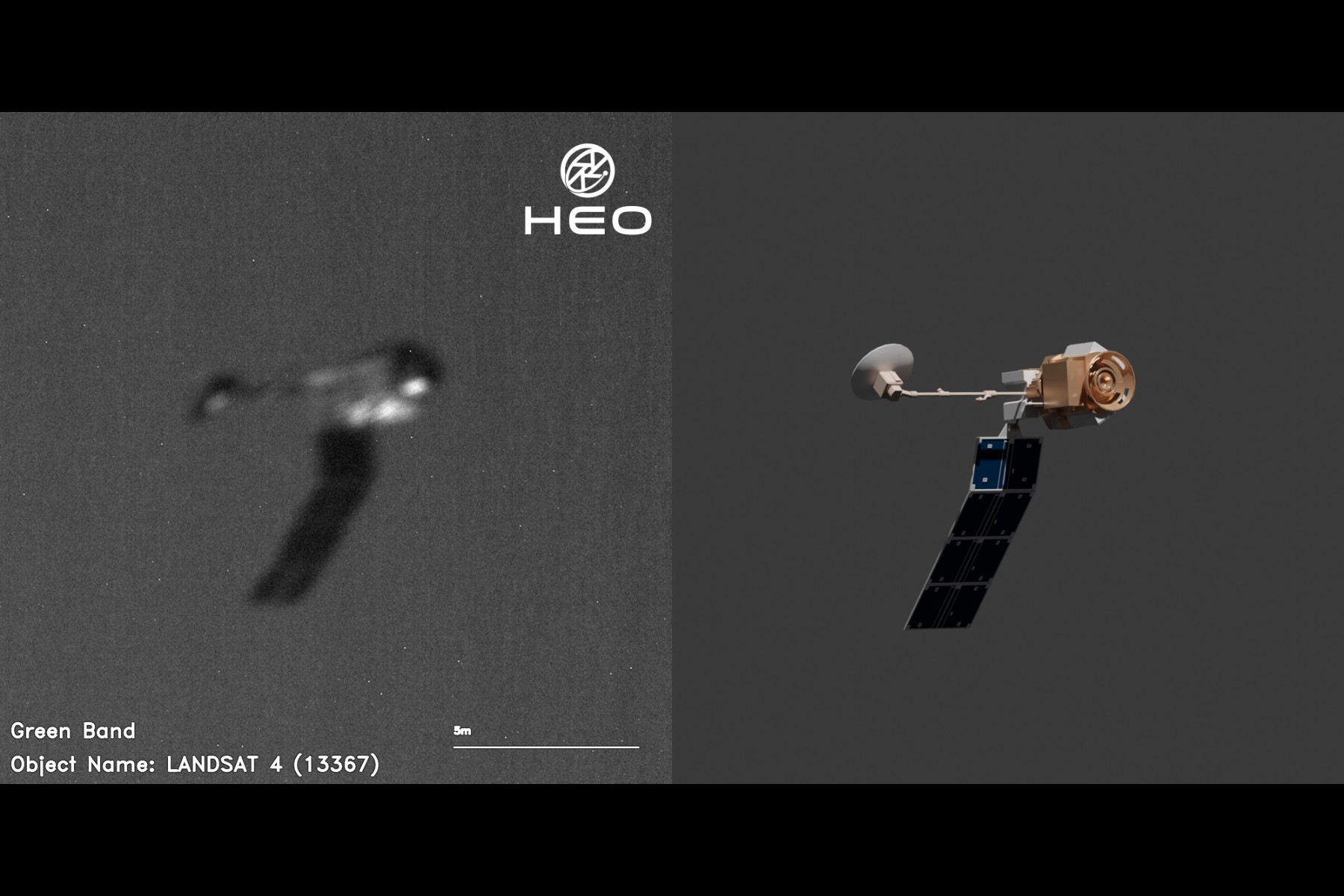

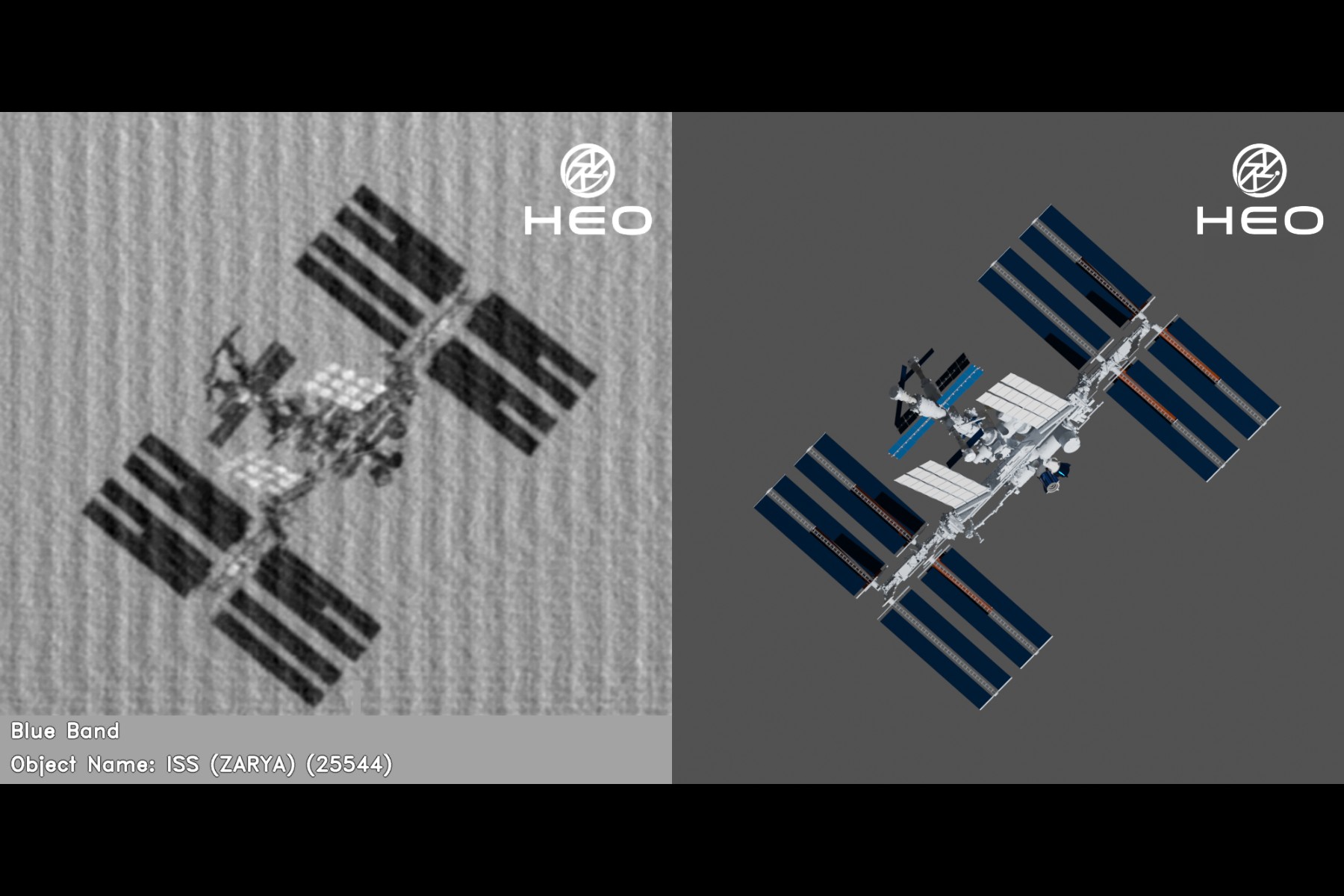

The software tasks the satellite during its regular orbit to snap a photo. The satellite points and captures the image in a “fly-by inspection”, while the software then detects the space object in frame. These fly-by inspections are not invasive and do it without need to manoeuvre and use propellant.

HEO Inspect’s photos offer “a new perspective on satellites and space debris”, Dr Crowe says. “Rather than trying to understand the positions of satellites and debris, we take resolved images from space.”

These images collect thousands of pixels to observe the shape, size, orientation, onboard equipment, any damage, and more, whether on a satellite or debris. HEO Inspect uses automated image processing and noise reduction.

The image processing software compensates for the fast movement of spacecraft, ensuring the images don’t appear distorted. This is crucial, when satellites are passing by each other at speeds of up to 54,000 kilometres an hour.

Software for sustainability

HEO’s software can assess the risk of orbital debris and evaluate the state and health of satellites. Their proprietary tools are designed to provide accurate insights to space organisations. HEO’s images are used to identify and characterise satellites after launch and to support re-entry predictions and active debris removal missions.

This debris or ‘space junk’ poses a major risk to space operations. As many as 27,000 pieces of debris are tracked by the US DoD’s Space Surveillance Network, with the majority larger than a softball.

This space debris threatens the sustainability of space operations and technologies, including those that support life on Earth. It can also pose threats to active satellites, manoeuvring and launches.

“We are helping organisations monitor some of the objects that pose the most risk, with large debris being able to be automatically monitored for size, shape and other important parameters to help manage the risk, whether in space, or while it re-enters Earth’s atmosphere.”

Those organisations could include commercial satellite operators and government agencies across the globe. HEO is currently working with a range of overseas partners including the European Space Agency and the UK Space Agency.

HEO continues to scale its operations. They received over $700,000 funding support for their Holmes imager from the Australian Space Agency via the Moon to Mars Supply Chain Capability Improvement Grant. Last year HEO raised $12 million in a Series-A funding round led by AirTree Ventures and backed by Salus Ventures.