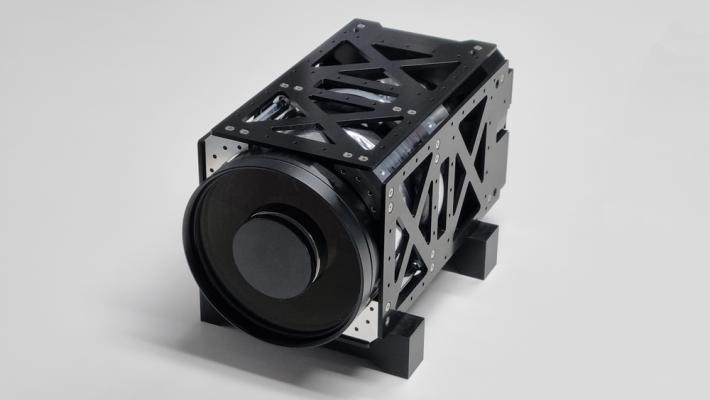

Infinity Avionics has created a powerful in-orbit camera system that allows the user to easily mix and match components.

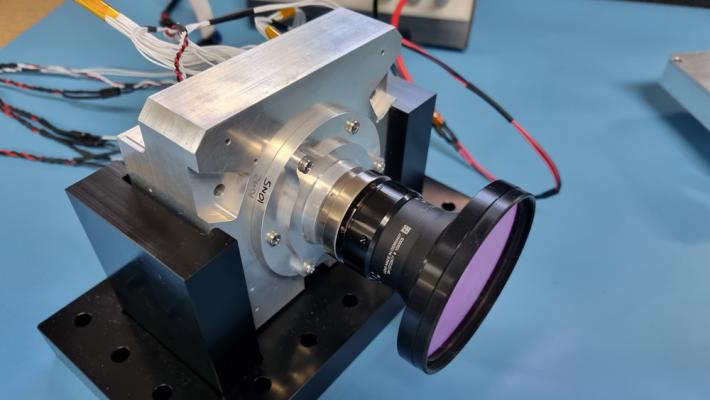

The Modular Imaging Unit (MIU), marketed as the Orion12MP, gets its name from its modular design. This means it’s not a fixed single piece of hardware – it can hook up to a range of different lenses, image sensors, external interfaces, and data storage options, depending on the needs of the customer. With a ‘plug-and-play’ design, it’s also quick and easy for users to customise their camera, instead of requiring complex and costly engineering processes.

The MIU design, along with Infinity Avionics as a company, grew from research at the Canberra campus of the University of New South Wales. At its launch, the Orion12MP became Australia's first commercial space imaging hardware product.

The system has a high image capture rate of 1000 frames per second, and is space-qualified for thermal vacuum, vibration, and shock. It also comes equipped with a non-volatile data storage system – which preserves data even if it is disconnected from a power source, similar to an everyday USB flash drive. These specifications make the Orion12MP ideal for Earth observation, monitoring debris and other objects in orbit, and supporting space robotics vehicles – such as landers and rovers deployed on missions to the Moon or Mars.

Orion12MP-550

“The use of vision systems on space-based assets is growing rapidly, due to increased complexity of modern space missions, improved capability of vision systems, and the proven high-value data these systems provide... It’s fantastic to be a part of this journey to contribute to the domains of Earth observation, space-based space surveillance, and space asset monitoring, providing imaging and vision systems designed and built right here in Australia.”

~ Igor Dimitrijevic, CEO, Infinity Avionics

Technology features

- High-resolution camera technology to support Earth observation, non-Earth imaging, space domain awareness, and space robotics.

- Modular design for easy customisation to support a range of image sensors, optical assemblies, and interfaces based on mission requirements.

- High frame rate capture – 1000 frames per second.

- Direct interfaces to AI-capable edge processors for data processing in orbit.

Project highlights

- Agency Supply Chain Capability Improvement grant awarded to support design, development, and testing of the modular camera technology.

- Australia's first commercial space imaging hardware product.

- Customised solutions successfully delivered to Australian and international customers, with further units under contract.

- Multiple technology partnerships established with domestic and overseas organisations.

Space-cams protecting satellite services

HEO's space imaging camera helps keep critical Earth-based services up and running.