Raytracer was previously awarded an International Space Investment Agency grant in 2020, which led to the development of an underwater virtual reality training simulation for astronauts called Titan Lake. It’s a world first VR capability that mimics micro gravity of space on Earth.

They have since developed new ‘Digital Twin’ technology, backed by the Australia’s Space Agency’s Moon to Mars Demonstrator Missions Grant program, and ‘CARBON’, a human to machine interface technology backed by the Agency’s Moon to Mars Demonstrator Feasibility Grant program.

Peter Clowes, Raytracer Co-Founder and Chief Executive Officer, describes the technologies as ‘revolutionary for exploration.’

Introducing Raytracer’s Digital Twin Technology

Raytracer’s Digital Twins are a real-time virtual replica of a physical asset or system. They can be used to run simulations and analyse real-time data on the asset’s performance. The twin looks and behaves just like its real-world counterpart. Engineers and scientists can use the Digital Twin to predict how physical assets will behave under different conditions, solve problems, and find efficiencies without having to tinker with the actual asset itself.

‘In many cases these assets are in remote or dangerous environments, so you don’t want to send people to inspect them,’ Mr Clowes said. ‘This can be incredibly useful for things as varied as operating vehicles on mine sites to planning a satellite mission.’

Digital Twin: space and Earth

Their Digital Twin tools can be used for designing spacecraft, improving the efficiency and performance of space missions, training and real-time decision making.

‘It allows for accurate simulations of how a satellite or spacecraft will behave under different conditions, enabling engineers to pre-emptively troubleshoot potential issues,’ Mr Clowes explained. This can be crucial for long-duration missions where timely corrective actions may not be possible.’

It also has noteworthy applications on Earth too.

In manufacturing, a Digital Twin can simulate production lines to optimise output and reduce waste. For urban planning, Digital Twins of cities can help model the impacts of various policies or infrastructure changes. In healthcare, Digital Twins of human organs are being researched to predict surgery outcomes or the effectiveness of medical treatments.

Introducing CARBON

CARBON is state-of-the-art software that combines Digital Twin, simulation, machine learning, robotics and visualisation tools to manage and maintain complex systems operating in remote environments like space.

The Agency’s Moon to Mars Demonstrator Feasibility Grant program was instrumental in supporting extensive testing and validation processes for the technology, while also facilitating research and pilot programs. ‘CARBON is a mission control centre that not only shows you what's happening now but can also predict future events and suggest optimal responses,’ he said.

It puts users in-situ with their assets. According to Mr Clowes, they can ‘make faster, smarter decisions by transforming re-active monitoring into pro-active advice’. Its capabilities are not limited to just space assets – it can also serve various applications ranging from industrial systems on Earth to cutting-edge space technologies.

CARBON: space and Earth

In terms of space exploration and operating satellites, CARBON brings ‘an unprecedented level of sophistication’, he said.

‘Its simulation capabilities can model complex space environments to predict various scenarios, ensuring that missions can adapt to changing conditions in real-time. The machine learning aspects allow for intelligent, adaptive decision-making, thereby reducing human error and increasing the efficiency of space missions.’

Additionally, CARBON's real-time 3D visualisation tools provide mission operators with a complete, dynamic view of assets in space, making the monitoring and control of these assets far more effective.

He says CARBON has various applications across the mining, resources, infrastructure, and manufacturing sectors.

‘Its advanced simulation and machine learning capabilities can transform sectors like manufacturing, energy, and logistics by offering predictive analytics and optimisation strategies.’

Space sustainability in action

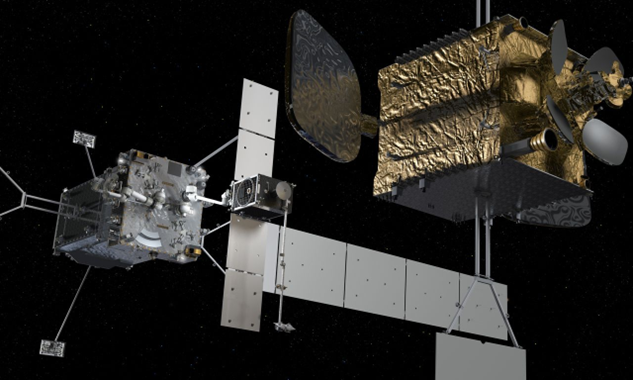

Raytracer have partnered with Optus, AROSE and QUT on a world-first demonstration of Australian capability in space sustainability. This collaboration utilises the CARBON technology. It will see a robotic support vehicle refuel the Optus D3 satellite in geosynchronous equatorial orbit. The vehicle will attach itself, extending the satellite’s operational life for another 6 years.